SUSTAINABILITY

DN AUTOMOTIVE is promoting transparent management to cultivate both sound corporate culture and mutual growth.

-

SUSTAINABILITY

-

Quality Management

Quality Management

DN AUTOMOTIVE places quality first for its business and pursues to achieve sustainable growth with customer satisfaction.

-

VISION

TOP QUALITY & PERFORMANCE IN THE WORLD

-

GOAL

DN AUTOMOTIVE secures competitiveness by obtaining global top quality for our products.

Business Strategy

-

Customer & Production Quality

Customer & Production Quality- Enhancing preventive quality management Standard consistency inspection (CP/SOS/parameter) Strengthening & expanding internal E/P inspection/validation Lot defect preventive activities for bushings

- Setting internal quality assurance system AQL development and extended application Limit sample/OPL/operator training

- Reinforcing activities to solve chronic issues Solving worst issues with CFT activities

Establishment of Internal Quality Assurance System

Establishment of Internal Quality Assurance System

-

Development Quality

Development Quality- Securing preventive quality through quality assurance activities for each APQP stage Utilizing development failure cases & lessons learned Reflecting improvements made in prototypes to production Impact analysis of distribution on product & process control

- Securing development quality for EVs Familiarizing APQP processes of new customers Reviewing quality requirements for optimal designs of new methods and systems to control motor vibration

Preventive quality assurance & early production stabilization

Preventive quality assurance & early production stabilization

-

Component Quality

Component Quality- Stabilizing quality with stronger management of suppliers

- Actively reflecting lessons learned from previous failure cases to design phases

- Early quality stabilization of development parts with tighter inspections from prototype stages

- Close cooperation with Purchasing team to enhance capability of suppliers with poor performance

Global supplier guidance enhancement & internal quality guarantee system establishment

Global supplier guidance enhancement & internal quality guarantee system establishment

Road map to achieve vision

-

Customer Complaint

(SPPS, Field action) Zero2017 ~ 2019

Flawless launching of new development parts

Flawless launching of new development parts- Enhancing maturity of drawing(2D, 3D)

- Reinforcing design review

- Reinforcing quality level of bought out parts

- Reinforcement of 4M change

- Error avoid process

-

Premium Quality

2020 ~ 2022

All customer requirement satisfied at MVBNS stage Customer oriented quality Zero PPM in customer complaints

All customer requirement satisfied at MVBNS stage Customer oriented quality Zero PPM in customer complaints -

Top Quality in the world

2023 ~ 2035

Shortening lead time in development phase Preemptive advanced technical solution providing Securing top class quality competitiveness Smart Factory Process Control using AI & IT

Shortening lead time in development phase Preemptive advanced technical solution providing Securing top class quality competitiveness Smart Factory Process Control using AI & IT

Certificates

-

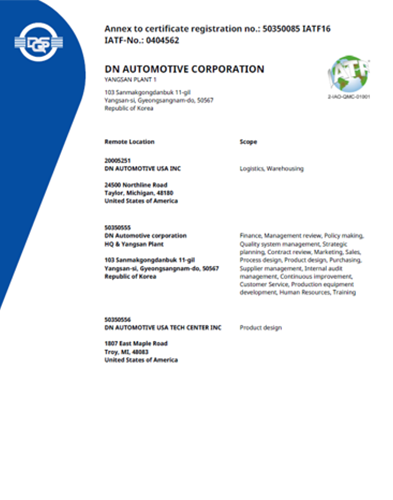

CERTIFICATE

CERTIFICATEAutomobile Quality Management System

- DN AUTOMOTIVE CORPORATION YANGSAN PLANT 1

- Quality Management System

- Scope : Design and manufacturing of anti-vibration rubber parts.

- IATF 16949:2016